Triol TM01

Downhole Measuring System

Maximum accuracy and protection of the oil production process

Downhole Measuring Systems Triol TM01 is designed for collecting, processing, displaying, transmitting and monitoring the required set of submersible equipment current parameters, downhole parameters and sensor values of surface wellhead equipment.

Safety and production process reliability

Downhole Measuring Systems Triol TM01 allows you to protect ESP and power cable line from overheating or mechanical damage, to reduce the percentage of equipment failure due to overheating, disruption of supply; optimize ESP operation, Linear Electric Submersible Pump, low-speed valve motor by maintaining their optimal performance rate; provide remote communication with the user via a cellular channel or cable line; improve the safety and production process reliability.

Successful operation in aggressive environment

Due to efficient algorithms for sensors status requesting and data operation management system, TM01 system provides continuous monitoring of equipment status and allows you to make timely decisions to optimize the performance indicators of the controlled equipment.

-

ISO 9001: 2015

-

2014/35/EU

Materials you may find useful

Distinctive benefits

Investment Savings

- More than 2 years of stable, long-term operation at the fluid temperatures up to +125° C, +150° C, +175° C with your perfect TM01 model match for your particular well at an acceptable price.

- Downhole Measuring System Triol TM01 can be performed in different types of enclosures depending on the available and planned surface equipment: in IP20 enclosure for integration into cabinets or in IP56 enclosure as a single equipment unit with its own display and communication channels.

- There’s a variety of submersible part designs depending on the aggressiveness of the fluid, thus reducing investments, both for less aggressive and more aggressive environments.

- Triol TM01 surface units transmit signals via additional digital and analog inputs, Ethernet, and RS482 / 232 communication channel, which allows cheaper collecting and processing data from wells.

- Integration of additional equipment to the lower submersible unit with suspension weight of 500 kg, eliminating the purchase of additional installation equipment.

- Stable operation with low-frequency motors (from 5Hz) allows using Triol TM01 in systems with low-speed motors, including PMMs.

- Resistance of submersible data channel to disturbances up to 1000 V, allowing Triol TM01 to operate with surface or submersible equipment that has temporary or permanent defects in the power circuit.

- Triol external choke guarantees that surface equipment is connected to the power cable and provide stable communication with the submersible unit even in case of no zero point in the step-up surface transformer. The choke is easily integrated into transformer case or located next to the transformer in a highly protected IP56 enclosure design.

- Wide range of flanges allows implementing of TM01 with positively any motor available in the industry, without additional investment.

Cost savings during commissioning and well operation

- High reliability of submersible part of Downhole Measuring System Triol TM01 due to the use of electronics appropriate to the temperature range, scrutinous selection of components, step-by-step testing during production and long-term testing at the final inspection reduce the cost of replacing the system during well operation.

- Increased system reliability due to backup of submersible unit in TM01-12 model is beneficial for high-tonnage and especially critical wells.

- Convenient operational documentation, well-thought-out installation kits for wells and online service support provide quick and error-free connection of TM01 to the well.

- Specially designed testing equipment (Test Units) allows testing performance of TM01 and submersible equipment during equipment descent into the well.

Increased production through quality and timely solutions

- Accurate pressure measurement at the pump intake from 0,05 MPa (5,8 psi) minimizes the fluid column above the pump and maximizes the production.

- Pressure measurement at the pump discharge from 0,05 MPa (5,8 psi) and temperature with a permissible error of ± 1 ° C allow surface equipment to automatically optimize the operating frequency and current of the motor, as a result, maximize the production.

- High speed of data exchange between submersible and surface units, stable communication channel ensures the constant availability of accurate and on-time data for making necessary decisions in order to maximize oil production.

- IP56 Surface Panel has a display with a user-friendly interface, which allows field personnel to quickly make decisions regarding the operation of the well itself and the equipment under control, as well as managing protection settings, which reduces equipment downtime.

- Installation of Triol modem in surface equipment, enable operators and technologist remotely monitor equipment status, allowing to quickly develop necessary solutions. Data received through the modem can be stored for convenient processing and prediction of equipment operation, collect statistics and plan diagnostic measures at the facility.

Increased service life of submersible equipment

- Accurate measurement of ambient temperature and ESP oil or ESP windings with a permissible error of ± 1 ° C allows protecting motors and pumps from overheating during their entire service life.

- Accurate measurement of vibration in all ranges of operation on three axes prevents the “flight” of submersible equipment, the destruction of tubing and extends the service life of submersible equipment.

- Accurate measurement of insulation resistance of the “three-phase oil transformer for electric submersible pumps – submersible cable – ESP” systems ranging from 10 to 10,000 kΩ allows evaluating the insulation level in the entire system, to keep transformer, cable and motor in operation for as long as possible.

Ensuring the safety of personnel at wells site

- Continuous, long-term, accurate and high-speed insulation measurement in submersible part guarantees the availability of information regarding safe working conditions for service personnel both in the system and on the well itself.

Options Available

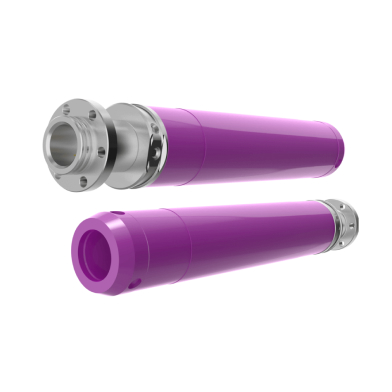

High-Voltage Choke

Triol High-Voltage Choke is an effective element of Downhole Measuring System Triol TM01 that provides a reliable and guaranteed communication channel between surface and submersible units of TM01.

Triol High-Voltage Choke creates an artificial Wye point in step-up transformers where output windings are connected in a “triangle” circuit thus ensuring a guaranteed connection of surface panel to submersible units. Inductor provides stable communication between surface and submersible equipment, filters out PWM modulation peaks of VSD.

Triol High-Voltage Choke includes fuses that are installed on each phase to protect TM01 surface equipment from accidents caused by phase imbalance in the power supply circuit of submersible equipment.

The choke can be installed either in a step-up transformer case or near transformer or VSD in its case with IP56 enclosure.

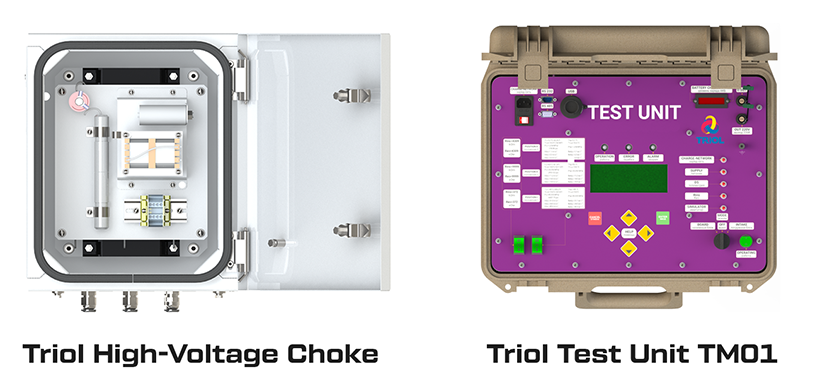

Test Unit

Triol diagnostic Test Unit is an irreplaceable element of Triol TM01 complex that accompanies its entire life cycle. Test unit is a symbiosis of a wide range of functionality, mobility, and simplicity of operation together with high reliability in various environmental conditions.

TM01 diagnostic complex guarantees the successful installation of Downhole Measuring System to submersible equipment and its launch into the well. Triol Test Unit provides an increased safety level, trouble-free operation both during pulling&running and installation process.

Triol Test Unit allows diagnosing both submersible and surface units of Downhole Measuring System TM01 – both before and during operation.

- ESP downhole sensor - TM01

- Add huge benefits to your great proposal

- Installation of the Surface Card and Choke

- Maximum productivity due to high accuracy TM01

- Triol TM01 Downhole Measuring System

Google

Google