Triol AT24

Industrial low voltage variable frequency drive

Operating simplicity and high-quality motor control

Variable Frequency Drive (VFD) AT24 series is designed to automatically control a wide range of production equipment, systems, and complexes with induction and permanent magnet synchronous motors in various processes. Triol AT24 VFD power range starts from 0.75 kW up to 3.2 МW with the voltage range 380 V, 480 V, 690 V.

Modern intelligent algorithms and elaborate interface

Triol AT24 VFD is equipped with special algorithms and functions to control motors in HVAC systems, oil production, mining, public utilities, heavy industry, as well as in elevator system and drilling rigs. Triol AT24 VFD is the harmony of operating simplicity and high-quality motor control. In combination with modern intelligent algorithms and elaborate interface, Triol AT24 VFD is your indispensable assistant!

8 distinctive lines for your beneficial implementation

Triol AT24 VFD is your reliable partner in investment and cost savings, commissioning at light speed, absolute comfort in operation, power factor advancing, and motors lifetime extension. Film capacitors in DC-link are long-life with MTBF 100 000 hours. No capacitors required within product lifetime. Forget about the need for periodic VFD switch-on for capacitors charging!

-

ISO 9001:2015

-

EN 61140

Distinctive benefits

Investment savings

- The wide variety of Triol AT24 VFD designs in terms of enclosure protection for indoor and outdoor installation, and operating temperature allows choosing the best option.

- All Triol AT24 VFD models are low-width for placing more VFDs in one row. There are many built-in options that also minimize general overall dimensions.

- Triol AT24 VFD makes it possible to control several motors simultaneously. No additional VFD required.

Cost saving

- Precision control. Triol author vector control algorithms have a function for automatically measuring motor parameters and provide high accuracy in controlling motor speed or motor torque.

- Implementation of Triol AT24 VFD significantly simplifies the operation in close-loop systems connecting three different types of encoders – incremental, absolute, sine/cosine. No additional spending, all set by default.

- Transient graphs. Generation and display of transient graphs directly on Triol AT24 VFD graphic panel is a defining benefit of the drive. This allows you to clearly control the processes, as well as fine-tune them and optimize regulation.

- No long downtimes. Automatic restart of VFD AT24 with a “catch on the fly” mode of induction motors ensures the minimum delay to the process recovery.

- “Kinetic buffering” – state-of the art algorithms guarantee continuous technological process even with 100% drops supply voltage. In this case, AT24 VFD operates it the control mode of DС-bus voltage value at the capacitors. Operating time in this mode can extend from 0.5 to 1.5 seconds. It depends on type mechanical characteristics of the drive. No downtime!

Commissioning at light speed

- Macros in the software of VFD graphic terminal. There’re sets of macros in the basic software for instant configuration of the control types (local, 2-wire, 3-wire) and assignment the sources of the frequency reference (from the built-in PID-controller, by discrete signals).

- Transfer settings between VFDs via a removable control terminal. If you have several identical Triol AT24 VFDs You spend time setting up only the first one. These settings are easily transferred to other AT24 VFDs by saving them in the removable control terminal memory. The next setting ups the of Triol AT24 VFD are performed in 7 simple clicks.

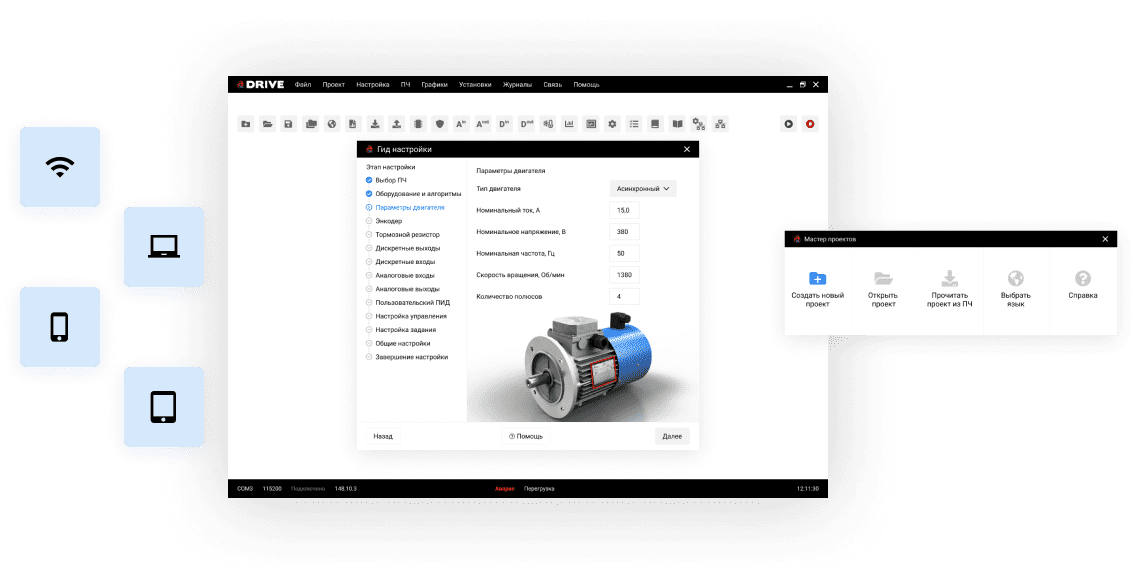

- Service Software via PC. Service software Triol Drive allows you to configure the drive both on-line when Triol AT24 VFD is connected to PC, and off-line, followed by recording the settings in the drive.

- Wi-Fi Wizard via smartphone. A Wi-Fi adapter with a step-by-step configuration assistant Triol Wizard provides fast and trouble-free configuration of all VFD functions using smartphone.

Comfort in operation

- Create maximum comfort in process control is much easier with Triol unique solutions for controlling Triol AT24 VFDs.

- Completeness of status information of the drive and access to all settings. The Start and Stop buttons are also available on remote controls.

- All recommended options of Triol AT24 VFD have supporting descriptions.

- There is no need to make adjustments in an uncomfortable position directly near the drive, for example, in a dusty workshop or under the scorching sun. Connect the control cable remotely and be in a place that’s convenient for you. The functionality of remote control completely covers local remote capabilities. Moreover, P24E has the ability to display transient graphs for more precise settings.

- Full immersion into Triol AT24 VFD adjustment and all its control shape. Triol Drive software for PC allows performing a detailed analysis and configuration of all output voltage control circuits, currents, torque and speed of the motor for various changes in the load on the motor shaft and operating modes.

- The ability to view graphs with the scaling function is vital for the precise adjustment of the regulation process.

- No possibility to connect a PC to Triol AT24 VFD for a long time in comfortable conditions? No longer a problem! Off-line customization is your reliable friend here.

- Just download Triol Drive software, select VFD type and perform the off-line configuration. Proceeding through the setup steps allows you to make all the necessary adjustments corresponding your requirements. All that remains is to create a file with the settings and connect your PC to Triol AT24 VFD for just a few minutes. Download the file and it’s done. Triol AT24 VFD is ready to launch.

- No external controller with software for managing and monitoring Triol AT24 VFD required. Integrated PI controller combined with the remote control is a great alternative to expensive PLCs.

Minimized maintenance

- Film capacitors in DC-link are long-life with MTBF 100 000 hours. No capacitors required within product lifetime.

- Reliable semiconductor devices and cooling fans ensure service life as well.

- Easily removable air filters allow performing periodic maintenance in minutes without stopping and disconnecting supply voltage from Triol AT24 VFD.

- Triol AT24 VFD removable high-power cell allows repairing without dismantling the entire cabinet. A convenient and elaborate process for lifting power cells allows easy installing involving one maintenance employee.

Power factor advancing and more

- increased power factor of frequency drive system up to 0.9-0.95

- reduced frequency drive impact on the supply network

- protection of frequency drive mains supply voltage from phase imbalance and thereby reduction the possibility of the drive shutdown due to poor power supply

- protection from an asymmetry of supply network phases

- protection from voltage dips

- protection from pulsed voltage surges generated by other operating devices

Motors lifetime extension

- dU / dt filter is designed to protect the drive motor from surges it produces and is connected at frequency drive output.

- Triol dU / dt filters allow limiting the voltage pulse rise on the motor windings to values less than 500 V / μs, enable to slow down windings insulation wear, thereby protecting them from a breakdown.

- Also, dU / dt filter allows using of a cable line up to 300 m long from the drive to the motor without harm to the latter.

- Implementation of frequency regulation is also possible for motors that are not intended for such operation due to poor insulation.

- Sine filter provides the motor with a close to sinusoidal THDu ≤ 5% voltage

- Common Mode Noise Filter reduces the effect of the frequency drive on other electrical accessories and extend electric motor lifetime. The filter is designed to reduce common-mode currents generated by discharges in the motor bearings from frequency drives during operation. Common Mode Noise Filter also reduces electromagnetic radiation from the cable, especially if the cable is not shielded.

Low-voltage VFDs operation

Setting up equipment using a smartphone, tablet or PC.

Wi-Fi remote configuration mode is implemented due to a wireless adapter with a built-in web-interface and Triol Wizard setup. Triol Wizard allows you to go through all the configuration steps and start the VFD from any device quickly and easily.

Triol Service Software for VFDs

Allows you to configure Triol AT24 VFD using a personal computer remotely or offline recording the VFD settings.

- Triol VFDs for mining applications

- Algorithm AT24 for controlling Sucker Rod Pump

- Triol AT24 for industrial applications

- AT24 DW line for Drilling industry

- Triol AT24 Series: intellectual universal unique ultra-adaptive

AT24 TRIOL Variable Frequency Drive Lineup

In electrical rooms with air conditioning and heating system

On ships in high humidity with chemically active salts in sea air

Google

Google