09 / 02 / 2022

9881 Views

Quite often users of medium voltage frequency drives are faced with the challenge of transferring the motor from the frequency drive to the mains in order to take another mechanism into control. Likewise, they face the challenge of the shockless transfer of the motor power from the mains to the VFD in order to take the mechanism into control. This problem is not new and in general, it is solved by many frequency drive manufacturers. However, there are cases where it is not possible to solve this problem even with time-tested equipment from leading manufacturers. In this article we will focus on such cases in detail and illustrate how the Triol AT27 frequency drives solve the problem and what benefits the customer will get from it.

How does the frequency drive transfer to the mains for electric motors and back?

To this day, there are three main ways to transfer the motor to the mains from the frequency drive and transfer the motor from the mains to the frequency drive.

Asynchronous: The oldest and simplest method of transfer of an electric motor to/from the mains could be found at facilities using multilevel frequency drives from 2005 to 2010. First of all, this method is found on fans with high inertia. This method consisted in accelerating the motor to a frequency that was 4-5% higher than the mains frequency. Then the high voltage was removed from the frequency drive output, a delay was set of 1.5-2 s, then the disconnection of the frequency drive output from the electric motor was instituted, and lastly, the direct start of the electric motor to the mains was completed. Transfer of the electric motor from the mains was carried out by disconnecting the electric motor from the mains, which was further caught on the fly by the frequency drive.

This method has proven to be excellent on fans with high inertia, but on non-inertial loads, it has proven to be insufficient for the following reasons:

At an asynchronous method of transfer to the mains, the electric motor connection occurs without reference to the phase and amplitude of the mains voltage, which leads to short-term inrush current in the electric motor windings and onset of shock torque. The magnitude of the inrush current can reach 12 times the nominal current of the electric motor, which can lead to the triggering of a relay or microprocessor protection and the supplying of the electric motor of the switchgear. But it can also lead to the sectional cell, with a further emergency stop of the entire section of switchgear 6, 10 kV; and

At an asynchronous transfer of the electric motor, driven by low-inertia load, the time of mains-scanning and the catch on the fly of the electric motor by the frequency drive can be comparable with the time of its full stop. In some cases, this leads to an emergency stop of the unit by technological protections.

Synchronous: is a modern and progressive way of transferring the electric motor to/from the mains. It is based on the principle of precise synchronization by frequency, amplitude, and output voltage phase of frequency drive and mains. It also maintains the current passing in the motor windings at the time of switching the motor from VFD to mains and reverse. This method eliminates any electrical and mechanical transients in the motor and the load, which makes switching the motor to one and the other side completely shockless.

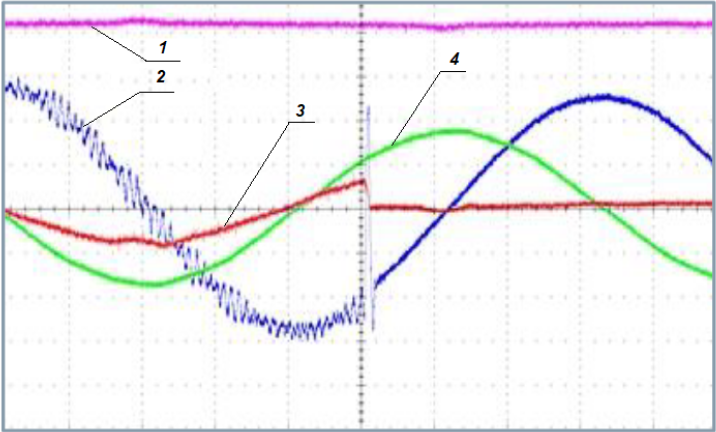

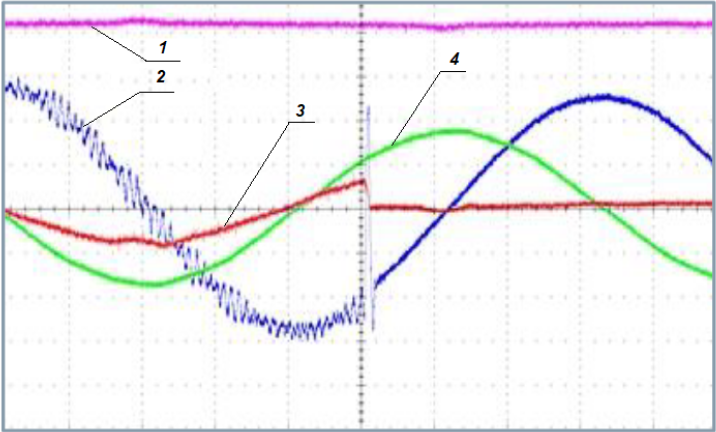

Pic 1. Diagram of motor transfer from VFD to mains:

- Voltage amplitude of the electric motor stator;

- Instantaneous stator voltage value of the electric motor powered by frequency VFD and mains;

- Instant control voltage value on the coil of the VFD output contactor;

- Instant stator current value of the electric motor powered by VFD and mains.

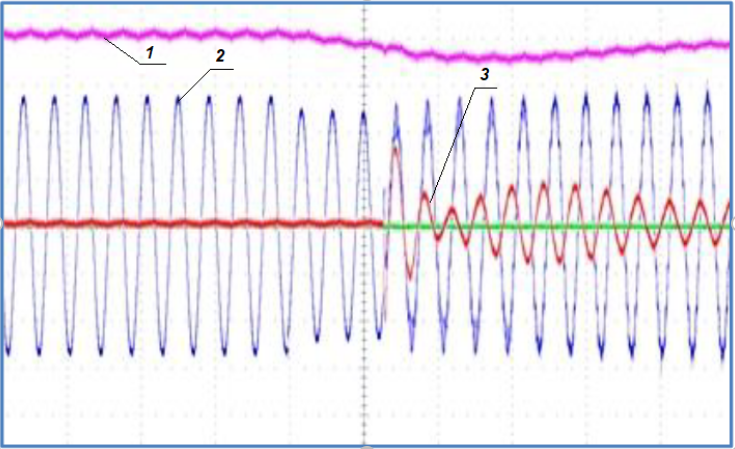

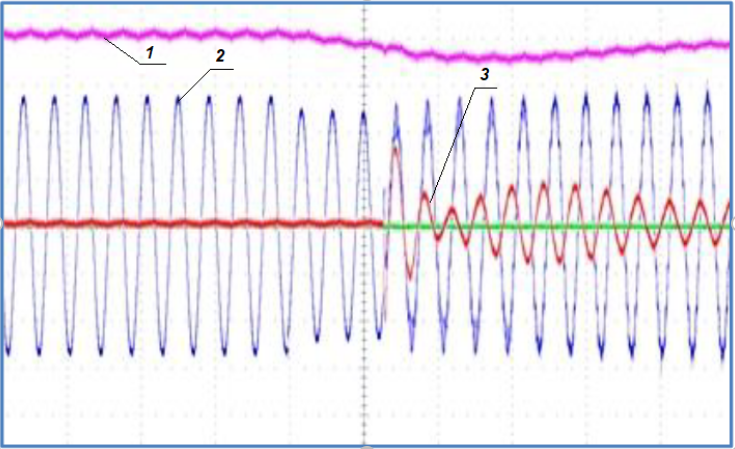

Pic 2. Diagram of motor transfer from the mains to the VFD:

- Voltage amplitude of the electric motor stator;

- Instant stator voltage value of the electric motor powered by VFD and mains;

- Instant stator current value of the electric motor powered by VFD.

Combined: This is a compromise between asynchronous and synchronous methods of the transfer of an electric motor to and from the main. The point of which is the fact of a current pause at the moment the motor switches from VFD to the mains and reverse, the value of which is disparately small compared with the asynchronous method. This method is used in VFDs, where the manufacturer could not solve the problem of the synchronous transfer of the motor to and from the main or when the use of an output reactor with sufficient inductance for synchronous switching leads to an unacceptable loss of the VFD output voltage.

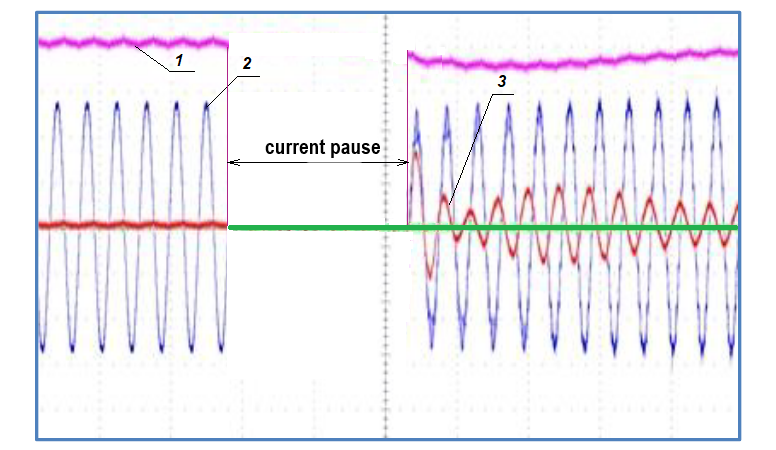

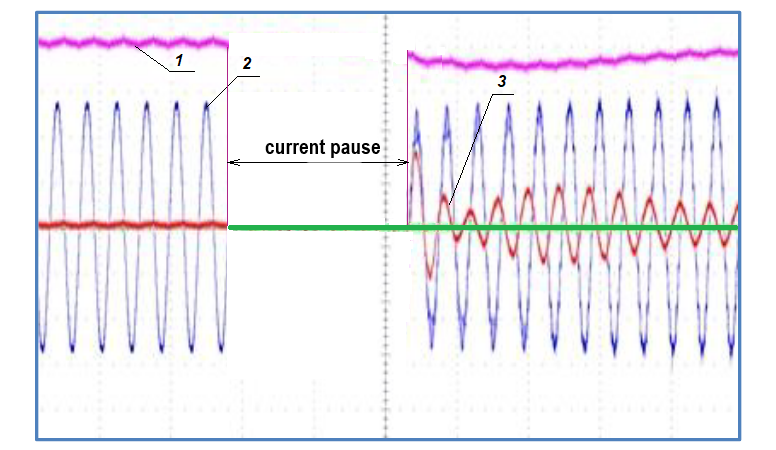

Pic 3. Diagram of motor transfer from the main to the VFD by the combined method:

- Voltage amplitude of the electric motor stator;

- Instantaneous stator voltage value of the electric motor powered by VFD and mains;

- Instant stator current value of the electric motor powered by VFD.

In addition to the above, the presence of a sine filter at the VFD output makes the task of the synchronous transfer of the motor from the mains more difficult. This requires additional hardware and algorithmic features. Currently, not all manufacturers of medium voltage frequency drives are able to solve such a problem.

What is the advantage of the Triol algorithm?

Triol Corporation has made tremendous progress in improving the algorithms of motor transfer to and from the mains. Today, the algorithm for the synchronous transfer to and from the mains has been supplemented with the functionality to synchronize the VFD output voltage by frequency, amplitude and phase and by the shape of the output voltage, replicating even the most "distorted" mains. So what does this give the user? Of course, it's a definite advantage! For the Triol AT27 VFD, the quality of the mains supply is not so critical. We also reliably transfer to the distorted mains and transfer motors from distorted mains to VFD, as from the mains where the level of higher harmonics meets the standard.

Whereas for other manufacturers the mains quality is an important factor in determining the performance of the equipment, we have solved the problem! This algorithmic advantage makes it possible to use the Triol AT27 drive even in the weakest and most problematic mains, which is impossible for other manufacturers' equipment.

In addition to this significant advantage, the Triol AT27 frequency drives do not require external synchronization with the supplying motor section. Synchronization of the measurement of supply mains parameters, including different sections, is implemented in the basic version of the AT27 frequency drive. This solution allows for its use as a soft-start device for powerful, heavy mechanisms such as ball mills, trunk turbo-compressors, and a number of other loads.

Conclusion

Our target and philosophy are to meet the needs of the most demanding customer! Our solutions fully cover all segments in which the Triol AT27 drives are used, making it an essential tool and the main hardy beast in production.

Don’t miss your elegant solutions!

-

check_circle_outline

Product news

-

check_circle_outline

Events

-

check_circle_outline

Discounts

-

check_circle_outline

Product portfolio innovations

Google

Google