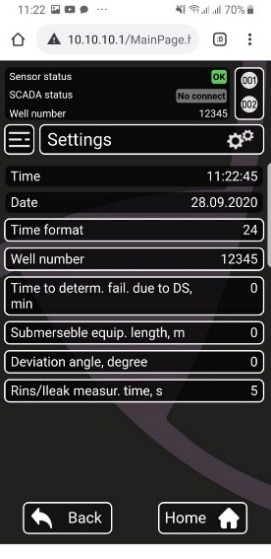

How did the technical capabilities of Triol TM01 become the factors of excellence for our customers? We will tell you this below. Meanwhile, good news: all interactions with TM01 can be carried out without leaving the car! This is possible thanks to the new format of the surface part of the TM01 series. Now you can control, configure, and read data from all models of the TM01 series using your mobile device.

At the same time, you do not need to have a stable mobile connection near the well; the data is transmitted via a wireless Wi-Fi network by the TM01 Triol surface block itself. We strive to improve usability, avoid the use of additional equipment for data processing, and jumpstart decision-making.

Possibilities of operating this way:

- Viewing the parameters of the well and submersible equipment on a mobile device; it does not require installation of additional apps

- Configuring the protection of equipment connected via digital outputs via a mobile device

- Viewing graphs of changes in telemetry parameters without special software or a laptop. Graphs can be built on the display of a mobile device:

- Motor and ambient temperatures

- Pressure at the pump inlet and outlet

- Motor vibration

- Leakage current.

The Wi-Fi network of each surface part of the TM01 is password protected from third-party connections.

You can learn more about this solution in the Operation Manual of the TM01 surface unit at the following link.

Variety of models and applicable in most existing wells.

Triol submersible telemetry systems have a wide range of models, which include both unique solutions for a specific well stock and universal solutions for compatibility with different types of motors, allowing you to choose the exact model of the series that will solve your problem and optimize your costs.

Let us consider various factors that determine the applicability of certain models of the TM01 series, as well as the influence of these factors on the cost of each solution.

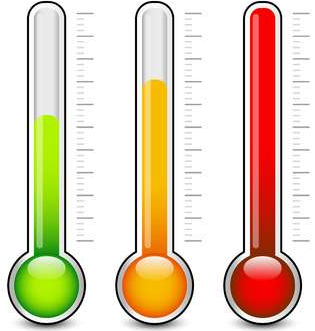

Well fluid temperature

Since the cost of telemetry directly depends on the temperature of its operation, Triol telemetry system is provided in three temperature ranges, so it is possible to not overpay for the components that are more expensive if the temperature in the wells does not exceed 257°F (125°C). If the fluid temperature is higher, telemetry is available in the model range for operating in wells with temperatures up to 302°F (150°C).

Finally, the current upper limit for Triol telemetry is operation in high-temperature wells with ambient temperatures up to 347°F (175°C).

Well pressure

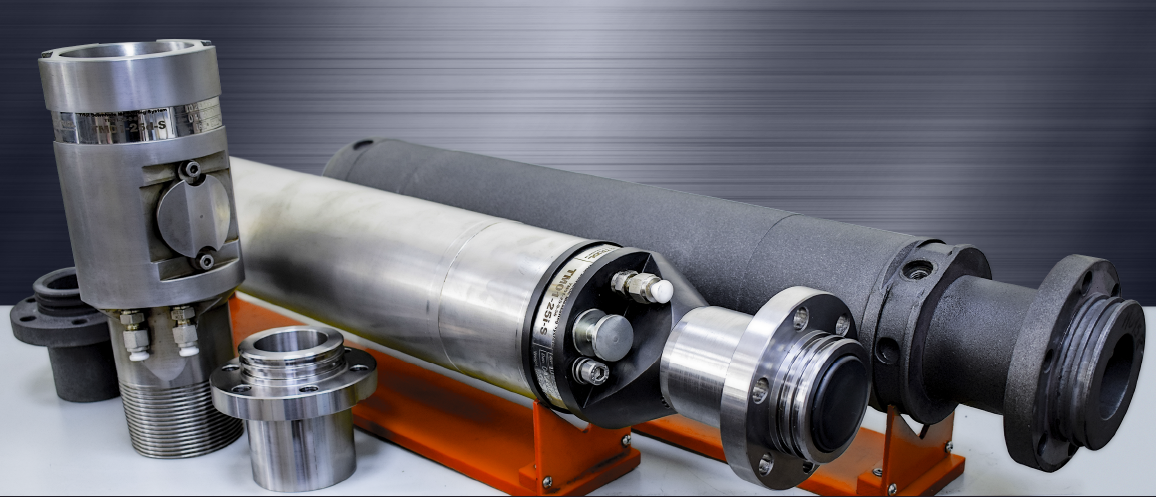

The shell of the TM01 submersible block is rated for 5800psi (40MPa) and is tested at 6100psi (42MPa). If necessary, it is possible to supply a submersible block with a shell for operation in wells with an ambient pressure of 8900psi (60MPa).

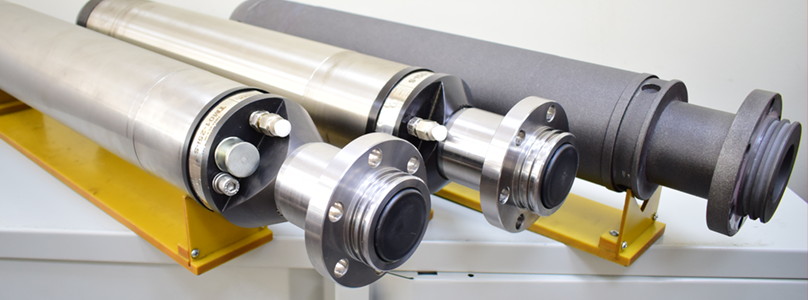

Compatibility with any submersible motor

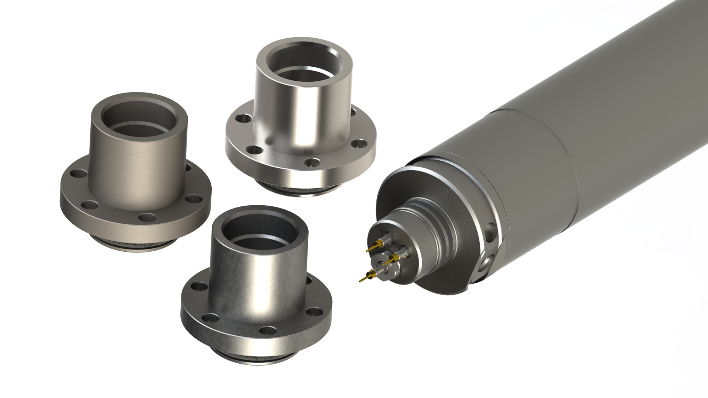

Manufacturers of submersible electric motors have a wide range of designs both in size and in connection dimensions, therefore the size of all Triol submersible units is 3.75 inches (96 mm), which allows connection of our telemetry to both 6"and 4" motors.

To dock the submersible telemetry unit with the motor, a removable flange is used. It can be replaced immediately in the workshop without additional adapters and connectors before the telemetry installation. This technical solution allows you to:

- reduce the number of sealing points, thereby increasing reliability

- avoid purchasing and storing additional adapters/connectors.

Basic solutions The main advantage of Triol telemetry is that there is an optimal solution in terms of technical capabilities and price for each task.

If your wells have a constant flow and do not need to maintain a low pressure at the pump intake, and at the same time the temperature of the formation fluid is up to 257°F (125°C), then the TM01-10 is the best solution for you. This model has the necessary functionality for the pressure at the pump intake, the ambient temperature and the motor winding temperature, vibration in three planes and the insulation resistance, all at an acceptable price.

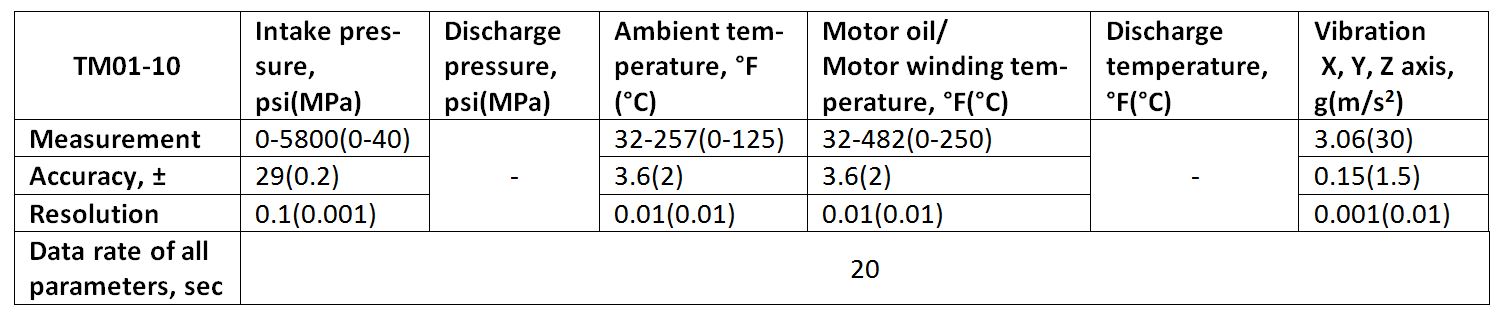

Submersible telemetry parameters TM01-10:

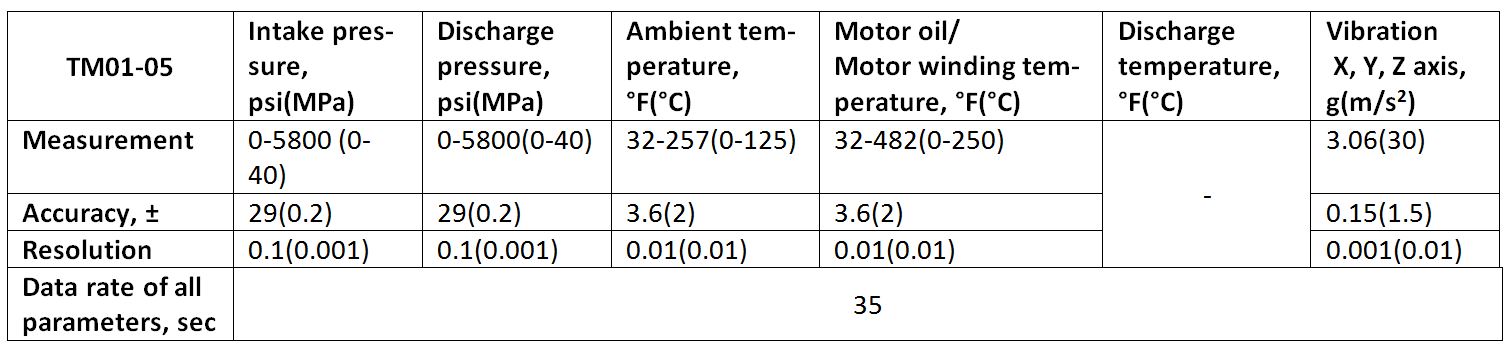

For a well with sandy problems and constant flow, which does not require low suction pressure, and where the formation fluid temperature is up to 257°F (125°C), the TM01-05 is the best choice. This telemetry is equipped with a pressure meas-urement sensor at the pump outlet, which allows monitoring and adjustment of pump operation to increase the resource or predict the replacement of equipment, reducing the well downtime.

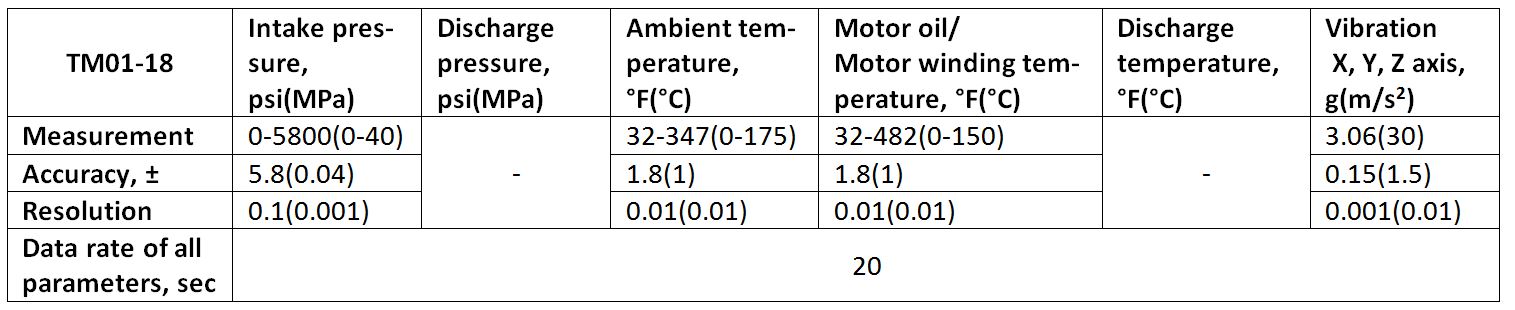

For operation in wells with temperatures up to 347°F (175°C) Triol supplies TM01-18 *series (this model is not commercial and is manufactured on request).

Submersible telemetry TM01-18 parameters:

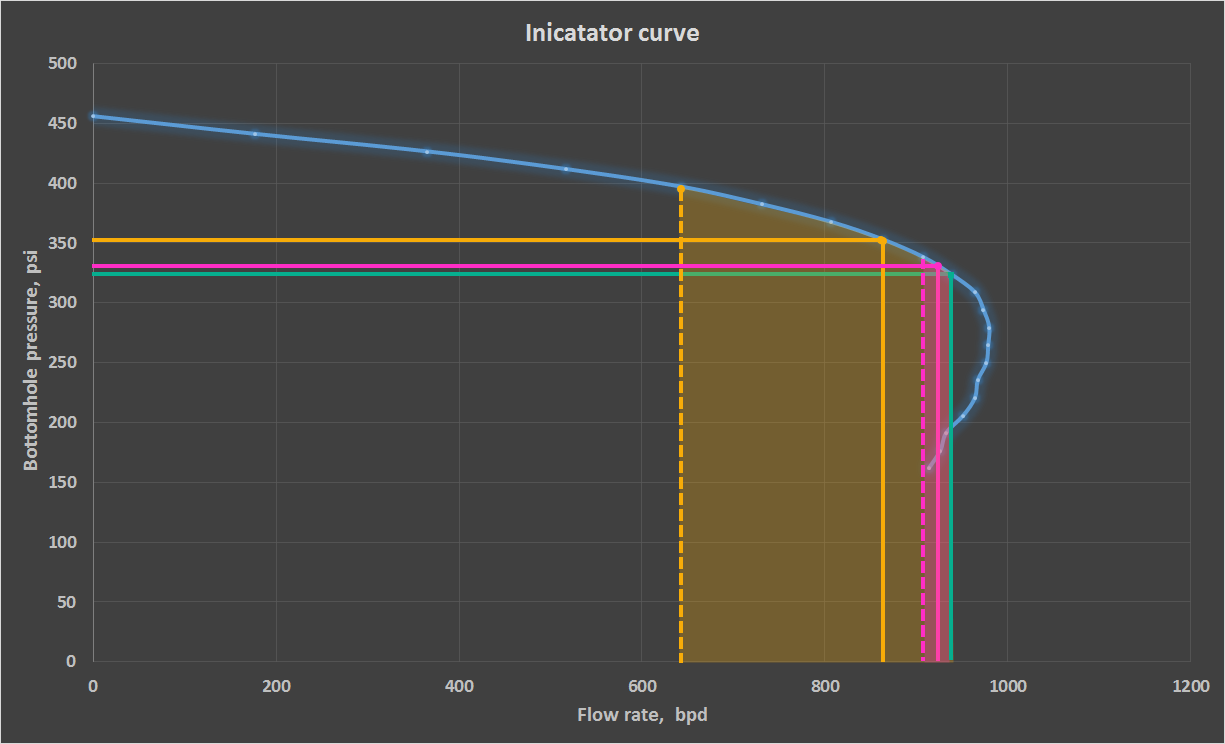

Maximizing production through accurate formation pressure measurement

To unlock the full potential of the formation, Triol Corporation has developed TM01-20 telemetry. Due to the measurement accuracy, telemetry can maintain a low dynamic level and thereby increase the inflow from the well. In addition, TM01-20 telemetry can operate at ambient temperatures up to 302°F (150°C).

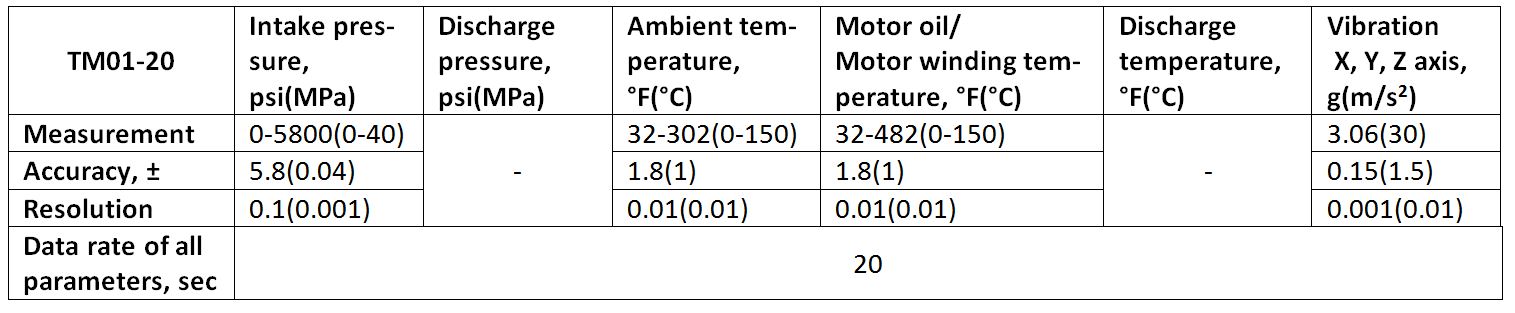

Submersible TM01-20 telemetry parameters:

Models TM01-25 and TM01-28 have the same high accuracy in measuring formation pressure, but their capabilities are not limited to this. Therefore, we will consider these models in the next section.

Reduction of scale deposits in the pump by measuring the temperature and pressure at the pump discharge.

Having carried out thousands of implementations in dozens of fields, we see that customers often face the problem of salt deposition and, therefore, a low resource of submersible equipment. To solve this problem, Triol has developed a series of submersible telemetry systems, TM01-15, TM01-25, and TM01-28 * (this item is not commercial and is made on request).

These TM01 series models are equipped with pressure and temperature sensors at the pump discharge. Availability of temperature data at the pump discharge allows control of the process of salt deposition, namely, it does not allow you to go beyond the temperature at which salts are released from the liquid, which allows an increase in the equipment resource. The models differ from each other by different operating temperatures: TM01-15 - 257°F (125°C); TM01-25 - 302°F (150°C); TM01-28 - 347°F (175°C).

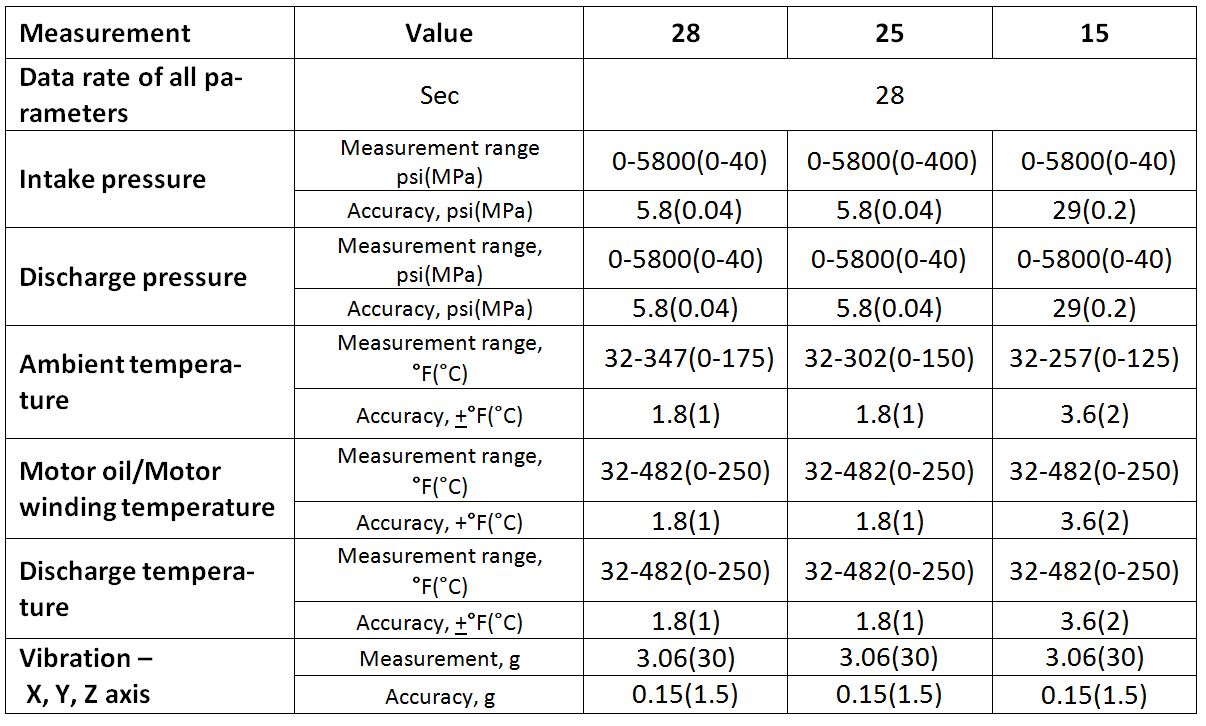

Submersible telemetry ТМ01-15, ТМ01-25, and ТМ01-28 parameters:

Triol has several additional unique solutions within the TM01 series; the following models are examples of such solutions.

Thru-shaft telemetry for operation with two motors operating in two different layers

TM01-06 (archive solution): telemetry is specially designed for installation between the motor and the pump and has a hole with sliding bearings under the motor shaft, which allows it to be installed in such an “unusual” place as at the junction of the motor and pump. Telemetry operates at a temperature range of up to 257°F (125°C). If you have a technical or technological need for placing a submersible telemetry unit between the motor sections, then the TM01-06 is specially designed for such an application.

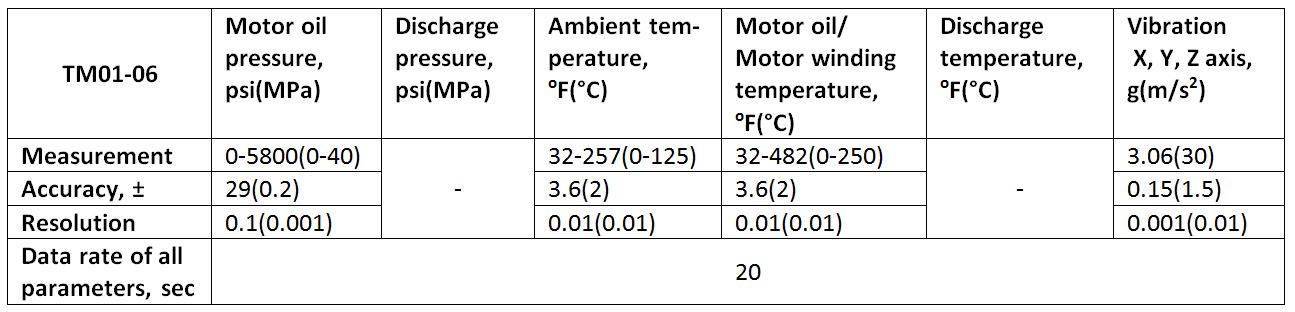

Submersible telemetry ТМ01-06 parameters:

Dual submersible unit for back-up submersible safety

TM01-12 is a unique technical solution, supplied specifically for highly productive and highly critical wells, in which deviation from the technology of production process leads to a decrease in production or to irreversible changes in the oil-producing formation itself, as well as for offshore operations, where the cost of well downtime is extremely high.

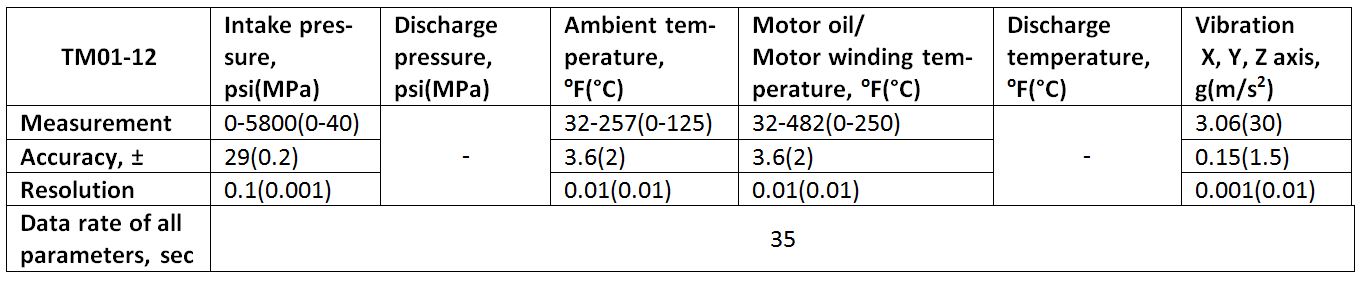

Submersible telemetry ТМ01-12 parameters:

Operation with low-speed motors with operating frequency close to the mains supply frequency

TM01-11 is designed for operation with low-speed motors with an operating frequency of up to 35Hz. ТМ01-11 is the best solution for progressing cavity pumps (PCP) operating with permanent magnet motors (PMM).

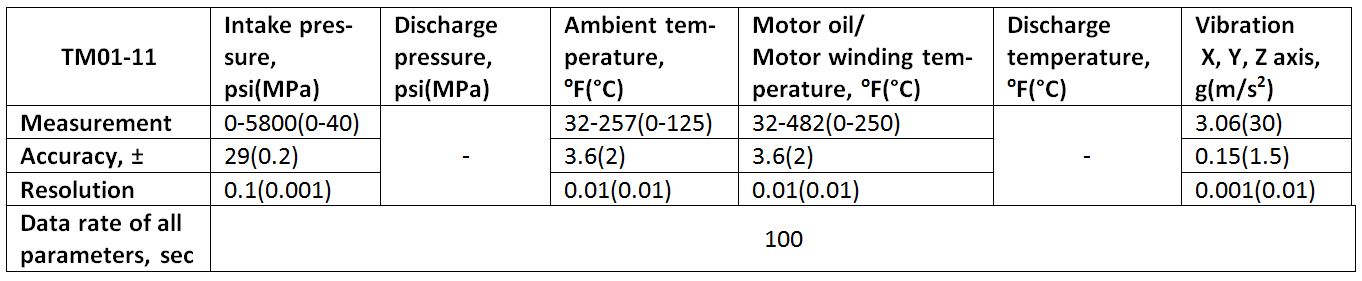

Submersible telemetry TM01-11 parameters:

The surface part of the TM01 also has several versions, depending on the tasks to be solved. A distinctive feature of the surface part is its versatility: regardless of the submersible part, you can use a surface part solution that best suits your task and operating conditions.

Triol Surface Card

The Triol Surface Card is IP20 rated for use inside variable speed drives or in other dust- and water-protected environments. The main task of the card is to receive data from the submersible unit and transmit it to the controller of the control system or to SCADA.

We have expanded the capabilities of this product and you can now view data as per the well and downhole equipment on the card screen, as well as plot graphs for a time interval by parameters such as pressure at the pump inlet and outlet, temperature of the motor winding and the ambient temperature, vibration and leakage current.

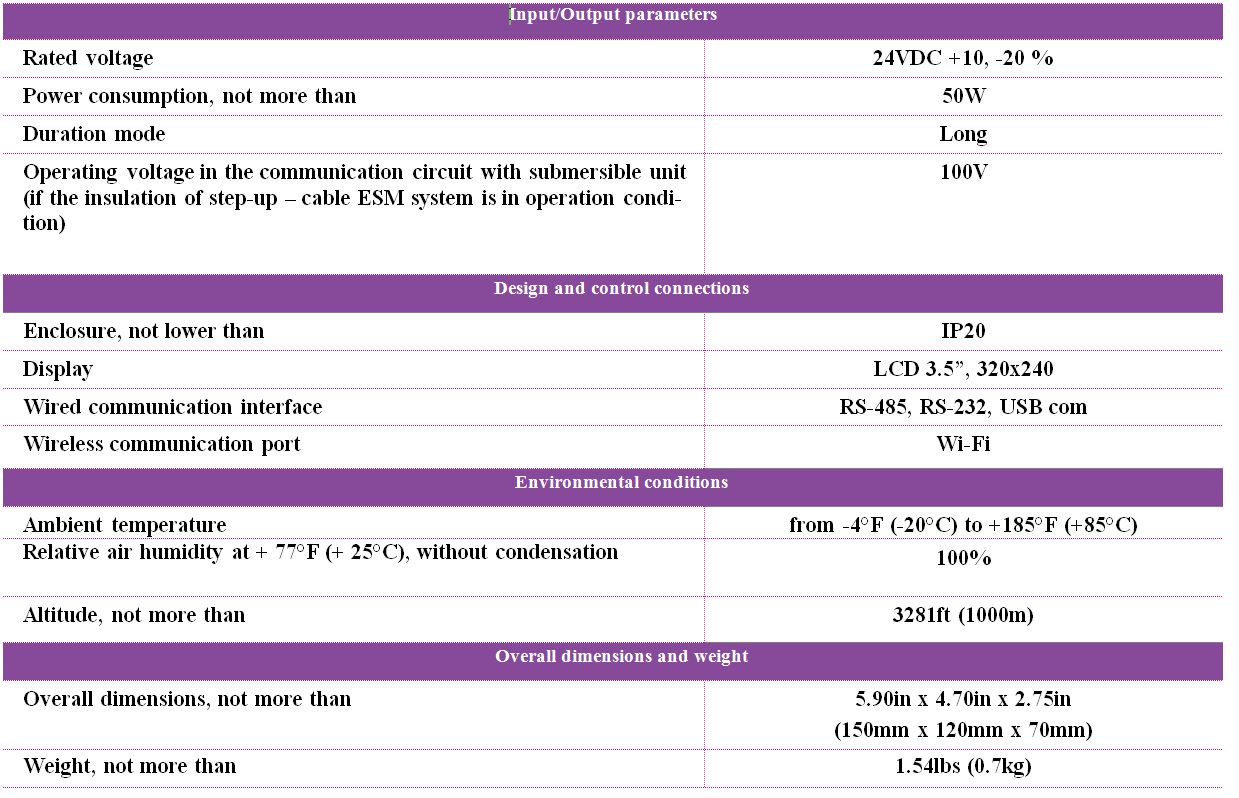

Surface Сard main parameters:

Triol Surface Panel

This version of the TM01 surface part offers the possibility of installation outside the speed drive, including on offshore platforms, since it has a NEMA4X degree of protection.

If the customer has a frequency drive with limited functionality, or there is no control display, with the help of this device you can configure the protection of submersible equipment by parameters such as pressure at the pump inlet and outlet, temperature of the motor winding and the environment, vibration and leakage current, view the values for these parameters, as well as display and diagram the parameters, thanks to the convenient 5 "display.

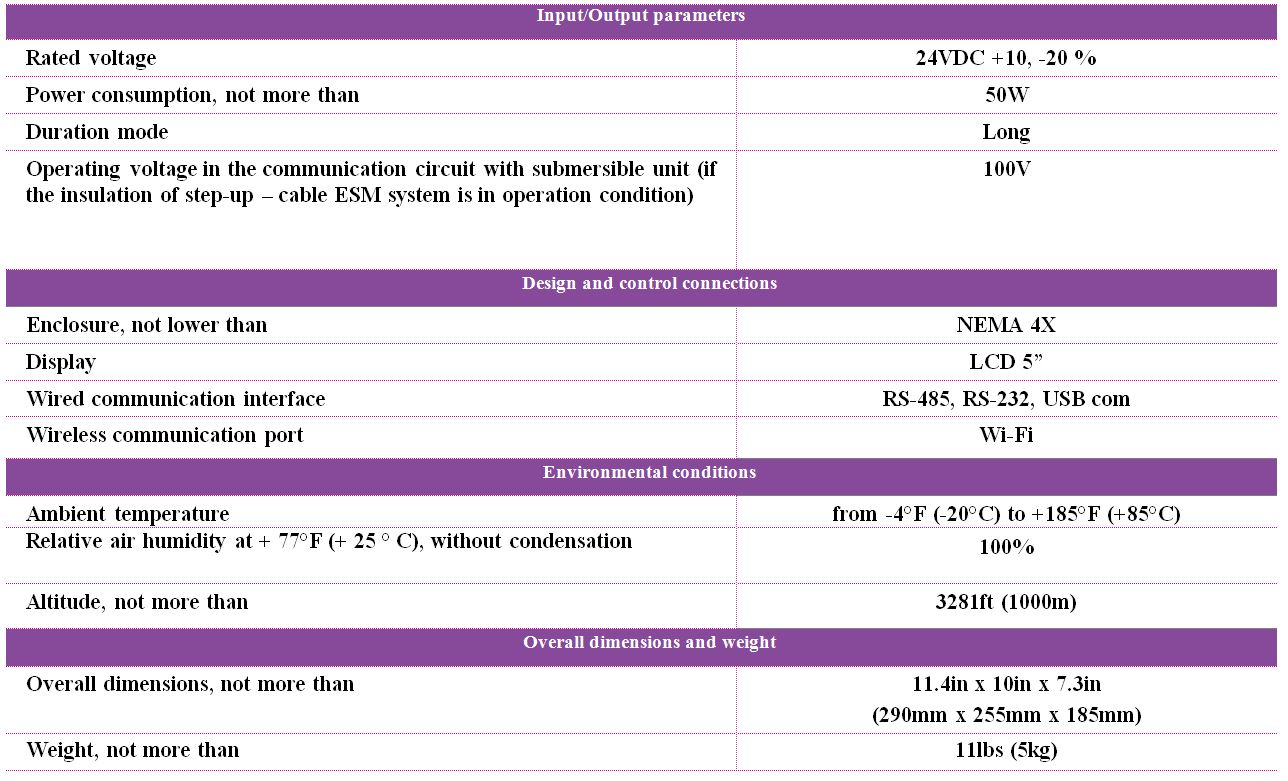

Surface Panel main parameters:

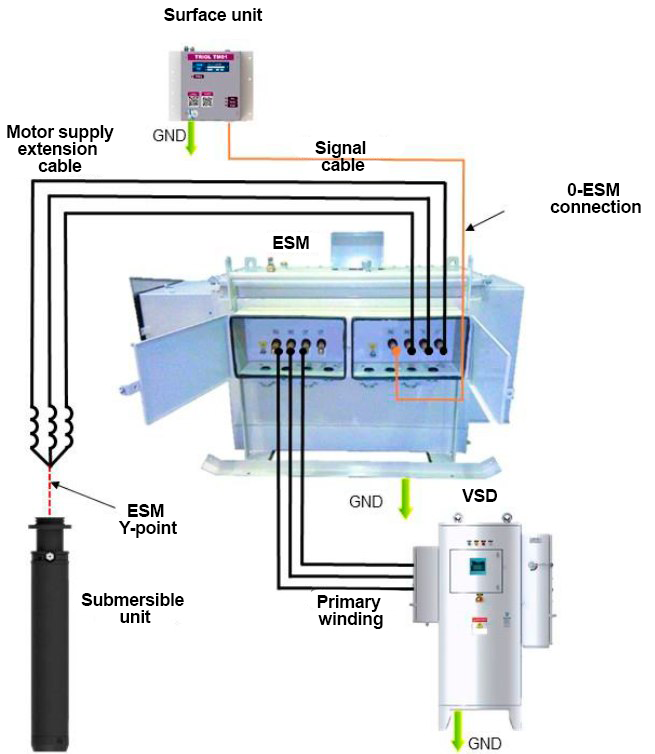

Triol High Voltage Chock

If you are using a Delta-Delta step-up transformer, or not using a step-up transformer at all, then you can create a zero point with the help of the Triol High-Voltage Choke.

Triol High-Voltage Choke IP65

Triol High-Voltage Choke IP56

The Triol High-Voltage Choke creates an artificial zero point in step-up transformers in which the output windings are delta-connected, thus ensuring the connection of the surface telemetry panel to the submersible units. The choke provides a stable connection between surface and submersible equipment and filters out the PWM modulation peaks from the variable speed drive.

The choke includes one fuse to protect the TM01 surface equipment from accidents caused by phase imbalance in the power supply circuit of the submersible equipment. Meanwhile the presence of one fuse reduces the time need to replace of the transformer threefold.

The choke can be installed inside the case of a power step-up transformer, as well as located near the power transformer or variable speed drive, in its own case with a IP56 degree of protection.

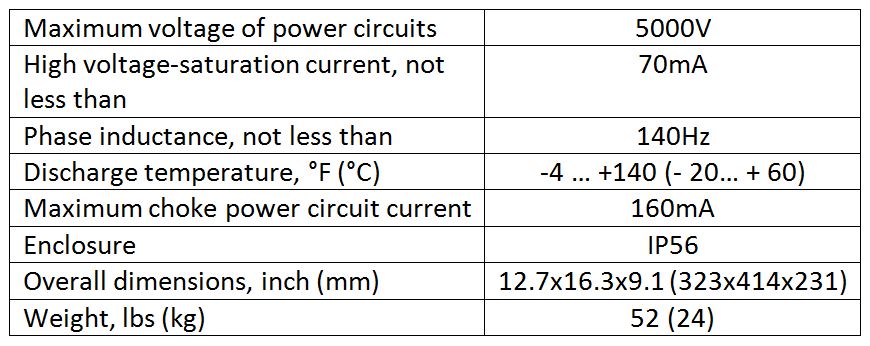

Triol High Voltage Choke main parameters:

Communication protocols: compatibility with any VSD and SCADA.

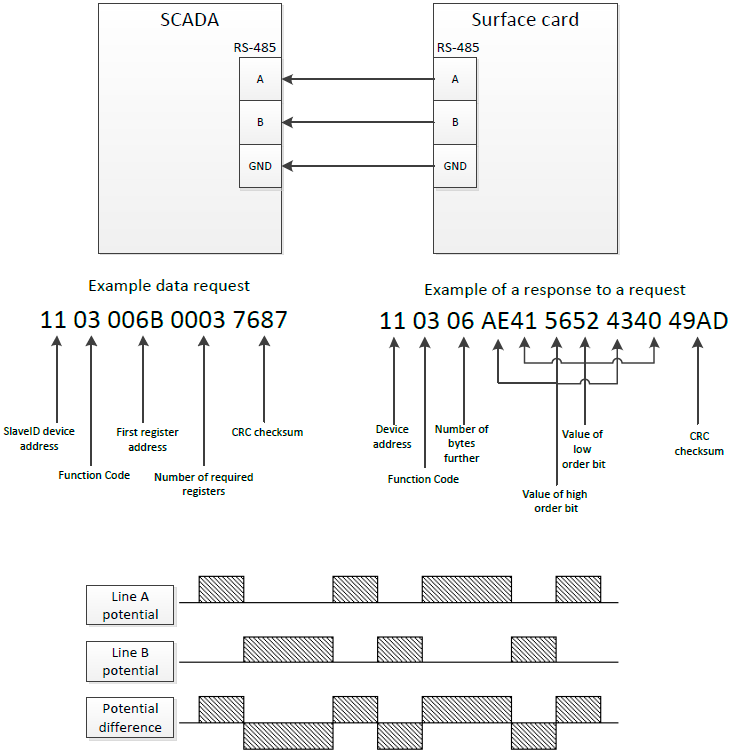

The Triol submersible telemetry system can be connected to any automated control system since Triol TM01 implements a standard Modbus address map. Modbus is widely used in the industry to organize communication between electronic devices and is used to transfer data through serial communication lines RS-485, RS-422, RS-232, and TCP / IP networks (Modbus TCP)

Thus, the diagram of the general connection of Triol TM01 in the well and on the surface can be depicted as follows:

Reliability

The reliability of Triol TM01 is close to 100% and is determined by two main factors - the quality of the components used and the smart technological process of production. TM01 uses AD converters ANA-LOG DEVICES, Texas Instruments, ATMEL, and AzSensCo pressure sensors. As for the ESM oil temperature sensors – in this case our company offers the customer a choice according to the type of the Triol telemetry sensor, which can operate with both RTD sensor and J sensors. We use only proven components and cooperate with reliable component suppliers.

The efficiency of the technological process of production depends on the reliability and stability of telemetry system operation; therefore, we pay special attention to the quality and reliability of each batch of Triol TM01 model. We carry out 100% testing and trials of every TM01 unit and every submersible and surface part of the TM01. In order to guarantee the reliability of TMS, each series of products undergoes life tests in the course of which we simulate real operating conditions and control the accuracy and quality of the transmitted data during the entire useful life of the TM01.

We invite you to take the opportunity to visit our factory. Under the existing circumstances, we can conduct a virtual tour!

Quality certificates

All Triol TM01 models are certified in accordance with the requirements of CE quality certificates. The manufacturing facility has been certified in accordance with the requirements of the Quality Management System ISO 9001 since 2002. We are flexible in our approach to certification of our products to strengthen cooperation with our partners and customers, and we are ready to meet the requirements of your regional standards.

Production experience and scope of application

Triol has produced TM01 since 2009. In 11 years, we have manufactured more than 20,000 TM01 systems. In 2020, the production volume will be approximately 3,000 systems.

Our telemetry successfully operates all over the world; our regular customers are companies from the USA, Russia, China, Indonesia, Uzbekistan, Romania, Ukraine, Kazakhstan, Turkey, and Egypt.

Availability

Triol maintains operational inventories of most models at any time in its warehouses in the USA and Ukraine. You can get to know the product in our workshop, as well as in our customers’ and partners’ workshops in almost all countries where oil is produced. Our service engineers will introduce you to the work of telemetry systems and present their features. We invite you to familiarize yourself with the current product catalog at the link.

Triol TM01 installation. Training of customer and partner personnel.

TM01 offers a simple and versatile way to mount and commission different TM01 models. We have provided the inter-changeability of the temperature sensor and the thermocouple, so you do not need to think about the design of the sub-mersible unit. We have provided the ability to replace the mounting flange for connecting motors of different sizes quickly and safely. If you use telemetry with temperature and pressure control at the pump discharge, the delivery set includes a special fitting and capillary tubes. Upon delivery, we provide the most versatile and complete assembly kit, which includes:

- Fitting

- Capillary tubes

- Temperature sensor

- Sealing rubber rings

It is possible to supply an assembly kit according to your requirements, considering the characteristics of your motor, pump, and operating conditions. Contact our service engineer or email us at: kostyuk@triolcorp.com

A trained specialist can install Triol telemetry in 10-15 minutes in the following 3 steps:

- Install the O-rings on the flange of the submersible unit

- Connect the motor oil temperature sensor and the power supply of the submersible unit by means of a simple plug-type connection

- Align the flange of the submersible telemetry unit with the motor support and tighten the resource fasteners.

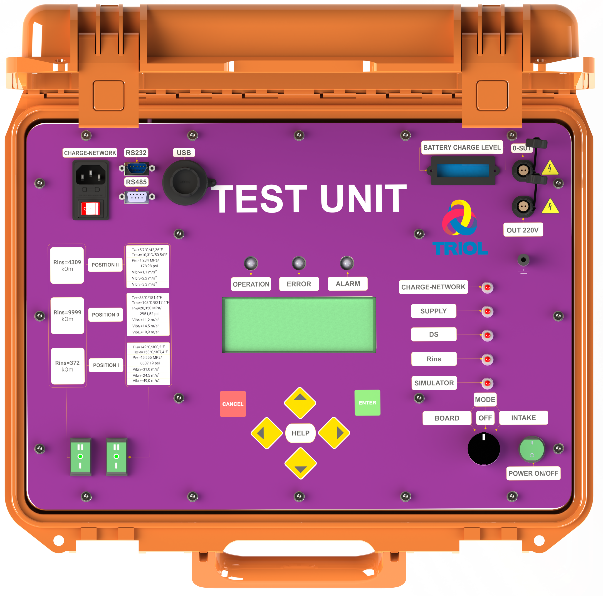

After connecting to the motor, you can test the submersible unit using Triol Test Unit without the need to connect the speed drive and surface telemetry equipment.

If you use sensors at the pump discharge (models TM01-05, 15, 25), then the discharge unit is installed and the sensors are connected when installing submersible equipment in the well using standard tools, threads and connectors. During the descent of the equipment, you can perform periodic tests and interrogate the parameters of the submersible telemetry unit using the Triol Test Unit.

You can view a detailed video of the TM01 installation and connection of submersible and surface parts here link.

Maintenance and repair

The TM01 design anticipates quick troubleshooting, maintenance, and repair. You can order all TM01 components and receive them as a spare parts kit. We offer our Test Unit diagnostic system for testing Triol TM01; it can be used to check the submersible unit after service.

In this article, we have described, both briefly and in detail, all the Triol TM01 models and components. We believe mastership requires details and passion. This is how beautiful and fundamental solutions are created.

Moreover, we have no doubt that every well of yours is worthy of this treatment – to be fundamentally profitable and elegantly equipped to maximize your economic results.

Promising developments

In conclusion, we would like to note that, even though Triol TM01 is already a rather mature product, we nevertheless have an idea for its development in our plans.

Additional measurements and technological assistant for TM01.

The first promising direction of TM01 development is to increase the number of measured parameters and automate technological processes. We are developing a solution for integrating additional sensors into TM01 such as:

- Flowmeter at the pump discharge

- Motor speed sensor.

The goal is to make the oil production process as efficient and productive as possible.

TM01 at 10,000psi.

The depletion of readily available oil reserves is forcing drilling deeper and deeper, and for this well stock the importance of using telemetry cannot be overstated. Therefore, we are developing a submersible unit that will operate at pressures up to 10,000psi or 69MPa.

Integration of TM01 into submersible motors.

One of the recently completed projects has been the integration of the TM01 into the installation of the Triol EP01 electric plunger pump. The task of integrating the submersible unit, data processing, and development of system control algorithms using the readings of the submersible telemetry unit has been solved. The solution made it possible to increase energy efficiency by 40%, increase the productivity of the formation due to the maximum decrease in the dynamic level, and increase the oil production rate by 25%. We are interested in integrating TM01 into your equipment and systems.

Don’t miss your elegant solutions!

- Product news

- Events

- Discounts

- Product portfolio innovations

More news

|

|

|

|

|

Google

Google